Automobile manufacturing giant Toyota announces that it will install next-gen computer vision company Invisible AI’s tech in its factories across North America.

The artificial intelligence-powered technology will enable the company to make more informed decisions about quality, safety, and productivity in its factories.

According to the company, it has cracked a deal with Invisible AI to upgrade 14 of its factories with Invisible AI’s cutting-edge computer vision technology.

Read More: EU accuses Apple of restricting rivals’ access to Payment tech

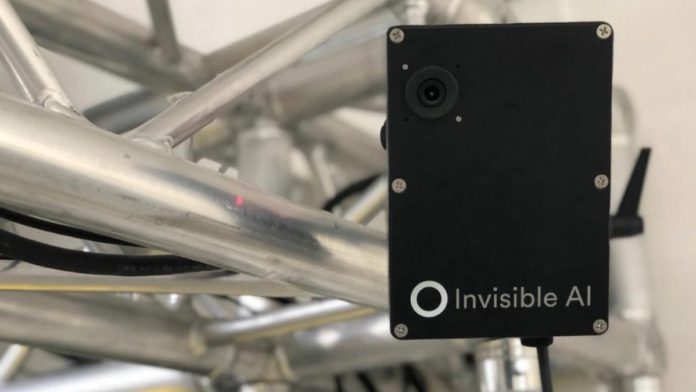

As per the terms of the agreement, Invisible will supply Toyota with the systems, beginning with a deployment of 500 AI edge devices at its Indiana factory.

Group Vice President, Vehicle Production Engineering & Manufacturing Production Innovation Center, Stephen Brennan, told Forbes, “We observe our employees assembling vehicles to identify inefficiencies and bottlenecks in their standardized work.”

He further added that Invisible AI systems would assist them in increasing the frequency and accuracy of process reviews, along with reducing the time required to identify inefficiencies across processes, allowing them to devote more time to improve.

Invisible AI’s technology employs 500 edge AI devices equipped with an NVIDIA Jetson chipset, 1TB of storage, and a 3D camera to track all floor activity. The technology can effectively provide real-time insights and information that could considerably help Toyota increase its teams’ productivity and accuracy.

“What we’re giving them is tools to be able to see more of what’s going on inside their facility, and they can then go in and correct any problems and any bottlenecks, making sure people are being safe,” said Co-founder and CEO of Invisible AI, Eric Danziger.

He also mentioned that what they have is a running AI computer vision model that is constantly processing all of the incoming videos to provide real-time information and insights while processing that data efficiently.